Available From TopLine: |

Bonding Wire Catalog Bonding Wire Catalog |

Made By: High Performance Bonding Wire Aerospace & Defense |

||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||

|

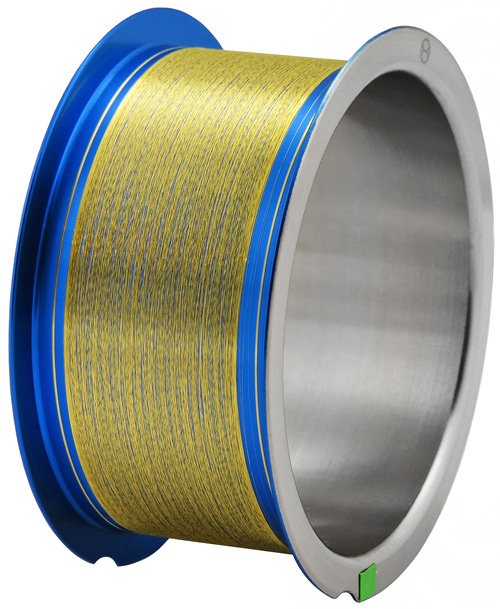

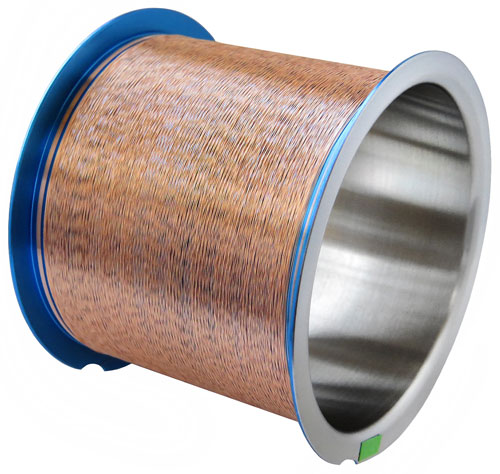

Au Gold Bonding Wire  GSA • GMH-2 • M3-Be |

Au Gold Ribbon Wire  AuR-Standard AuR3-Be Doping Gold Ribbon |

Aluminum Bonding Wire  TABN Al-Si1% |

All Types Gold Wire  General Purpose Gold Wire |

References: HS • Applications ±Tol • RLC • AWG Handling • EL • BL Part# • Order Nbr Fusing Current Spool • Green Start Bonders • Capillary Library & Reference |

|||

| About TANAKA: TANAKA Precious Metals is the premier manufacturer of bonding wire to the semiconductor, defense and aerospace industry. TANAKA also offers a full range of Gold (Au), Silver(Ag), Aluminum (Al), bare Copper (Cu) and Palladium Coated Copper (PCC) covering all applications of wedge, ball and bump bonding. High performance flat Gold for RF modules and power applications. Now available on 1/2-inch "H" spools for manual bonders. |

Green=Start • Red=End.  |

|

Gold (Au) High Performance Bonding Wire • Other Sizes Gold (Au) High Performance Bonding Wire • Other Sizes |

||||||||||

| Type | Alloy | Ø Diameter ±1% μm |

Breaking Load (gf) |

El (%) |

Spool Size | Length Meters |

Length Feet |

Part Number | Order Nr | |

| GMH-2 | 4N Au 99.99% Gold |

Ø 20µm (Ø 0.8 mil) |

5.0 gf Min | 3~5% | AL2(W) 2-Inch |

100m | 328ft | GMH2-20A100(EL3~5) | 302202 | |

| GSA | 4N Au 99.99% Gold |

Ø 25µm (Ø 1.0 mil) |

9.0~14.0 gf | 3~6% | AL2(W) 2-Inch |

100m | 328ft | GSA-25A100(EL3~6) | 300254 | |

| GSA | 4N Au 99.99% Gold |

Ø 25µm (Ø 1.0 mil) |

9.0~14.0 gf | 2~6% | AL2(W) 2-Inch |

100m | 328ft | GSA-25A100(EL2~6) | 300258 | |

| M3 | 4N Au 99.99% Gold Be Doping |

Ø 25µm (Ø 1.0 mil) |

9.0 gf Min | 3.5~6% | AL2(W) 2-Inch |

100m | 328ft | M3-25A100(EL3.5~6) | 303254 | |

| GMH-2 | 4N Au 99.99% Gold |

Ø 38µm (Ø 1.5 mil) |

15.0 gf Min | 0.5~3.5% | AL2(W) 2-Inch |

100m | 328ft | GMH2-38A100(EL3.5) | 302382 | |

| ||||||||||

| Note 1: Wire diameter available: 12.5µm , 15µm , 18µm , 20µm , 23µm , 25µm , 28µm , 30µm , 32µm , 33µm , 35µm , 38µm , 50µm | ||||||||||

| Note 2: Green=Start • Red=End. | ||||||||||

AuR Type - Gold (Au) High Performance Bonding Ribbon 4N • • Other Sizes AuR Type - Gold (Au) High Performance Bonding Ribbon 4N • • Other Sizes |

|||||||||||

| Type | Alloy | Thickness | Width | Breaking Load (gf) |

El (%) |

Spool Size | Length Meters |

Length Feet |

Part Number | Order Nr | |

| AuR | 4N Au 99.99% Gold Ribbon |

12.7um (0.5mil) |

75um (3.0mil) |

14.3~29.5 gf | 1~3% | AL2 | 50m | 150ft | AuR-75x12.7A50(EL1~3) | 316521 | |

| |||||||||||

| Note 1: AuR Type Au Gold ribbon is fabricated using a dry process. No lubrication oils are introduced during fabrication. Excellent corrosion resistance. | |||||||||||

| Note 2: Tanaka AuR ribbon is made using a rolled process with stress relief (SR). Edges are smooth without sharp edges. Good surface smoothness. | |||||||||||

| Note 3: Tanaka's specially formulated winding process assures consistent de-spooling and smooth bonding. Not parallel winding. | |||||||||||

| Note 4: Flat Au ribbon provides an excellent solution for RF devices. | |||||||||||

| Note 5: See alternative Flat Au ribbon with Be (Beryllium) additive for Stability 353xxx AUR3 series. • Other Sizes | |||||||||||

| Note 6: AuR gold ribbon wire made in Japan. | |||||||||||

| Note 7: Green=Start • Red=End. | |||||||||||

AuR3 Type - Gold (Au) Be Doping Bonding Ribbon 4N • • Other Sizes AuR3 Type - Gold (Au) Be Doping Bonding Ribbon 4N • • Other Sizes |

|||||||||||

| Type | Alloy | Thickness | Width | Breaking Load (gf) |

El (%) |

Spool Size | Length Meters |

Length Feet |

Part Number | Order Nr | |

| AuR3 | 4N Au 99.99% Gold Ribbon Be Doping |

12.7um (0.5mil) |

75um (3.0mil) |

10 gf Min | 1~5% | AL2 | 30m 50m |

100ft 164ft |

AuR3-75x12.7A30 AuR3-75x12.7A50 |

353523 353520 |

|

| 25um (1.0mil) |

50um (2.0mil) |

18.8~38.8 gf | 2~6% | AL2 | 30m 50m |

100ft 164ft |

AuR3-50x25A30 AuR3-50x25A50 |

353103 353100 |

|||

| |||||||||||

| Note 1: AuR Type Au Gold ribbon is fabricated using a dry process. No lubrication oils are introduced during fabrication. Excellent corrosion resistance. | |||||||||||

| Note 2: Tanaka AuR ribbon is made using a rolled process with stress relief (SR). Edges are smooth without sharp edges. Good surface smoothness. | |||||||||||

| Note 3: Tanaka's specially formulated winding process assures consistent de-spooling and smooth bonding. Not parallel winding. | |||||||||||

| Note 4: Flat Au ribbon provides an excellent solution for RF devices. | |||||||||||

| Note 5: Flat Au ribbon with Be (Beryllium) additive for stability. • Other Sizes | |||||||||||

| Note 6: AuR gold ribbon wire made in Japan. | |||||||||||

| Note 7: Green=Start • Red=End. | |||||||||||

Aluminum-Silicon (Al-Si1%) High Performance Bonding Wire • Other Sizes Aluminum-Silicon (Al-Si1%) High Performance Bonding Wire • Other Sizes |

||||||||||

| Type | Alloy | Ø Diameter ±1% μm |

Breaking Load (gf) |

El (%) |

Spool Size | Length Meters |

Length Feet |

Part Number | Order Nr | |

| TABN | Al Si1% Aluminum |

Ø 25µm (Ø 1.0 mil) |

15.0 ~17 gf | 1~4% | AL2(W) 2-Inch |

100m | 328ft | TABN-25A100(EL1~4) | 40325x | |

| ||||||||||

| Note 1: Uniform distribution of Si and stable mechanical property. Annealed. Heat treated. Stress relieved (SR type). | ||||||||||

| Note 2: TABN has good corrosion resistance under PCT (Pressure Cooker Test) with high humidity and temperature. | ||||||||||

| Note 3: Wire diameter available: 12.5µm , 15µm , 18µm , 20µm , 23µm , 25µm , 28µm , 30µm , 32µm , 33µm , 35µm , 38µm , 50µm | ||||||||||

| Note 4: Green=Start • Red=End. | ||||||||||

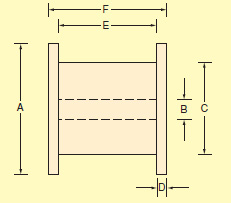

Spool Reference Dimensions |

Spool Dimensions | Box Dimensions & Spool Quantity | ||||||||||||||

| Material | Type | A Flange Diameter |

B Shaft Diameter |

C Hub Diameter |

D Hub Thickness |

E Winding Width |

F Overall Width |

Spool Style |

Part Nbr Code |

White Inner Box QTY Spools L=7.25" W=12.5" H=4.0" |

Small Outer Box QTY Spools L=8.25" W=13.25" H=10" |

Medium Outer Box QTY Spools L=13.25" W=24" H=10" |

Large Outer Box QTY Spools L=13.25" W=24" H=14" |

|||

| Aluminum Spools |

AL-2(W) 2x1 Inch  |

58.5mm | 48.8mm | 50.3mm | 0.75mm | 26.4mm | 27.9mm |

AL-2(W) AL-2 |

A | 20x Spools | 40x Spools | 120x Spools | 180x Spools | |||

| AL-2(WNi) 2x1 Inch Conductive Hub  |

58.5mm | 48.8mm | 50.3mm | 0.75mm | 26.4mm | 27.9mm | AL-2(WNi) | C | 20x Spools | 40x Spools | 120x Spools | 180x Spools | ||||

| AL4(W) 2x2 Inch  |

58.5mm | 48.8mm | 50.3mm | 0.75mm | 45.5mm | 47.0mm | AL-4(W) | B | 12x Spools | 24x Spools | 72x Spools | 108x Spools | ||||

| AL-4(WNi) 2x2 Inch Conductive Hub  |

58.5mm | 48.8mm | 50.3mm | 0.75mm | 45.5mm | 47.0mm | AL-4(WNi) | N | 10x Spools | 20x Spools | 60x Spools | 90x Spools | ||||

| AL-1/2 Half-Inch  |

17.4mm | 12.7mm | 13.5mm | 0.40mm | 18.3mm | 19.1mm | AL-1/2 | H | 5x spools | - | - | - | ||||

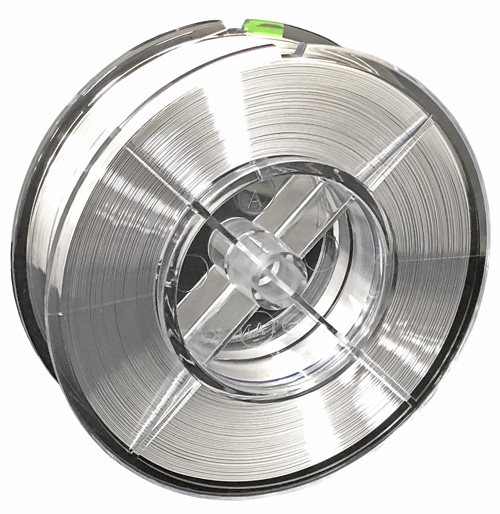

| Polycarbonate Spools |

No.88 3.5 Inch  |

88mm | 10mm | 50mm | 3mm | 25mm | 31mm |

No.88 Ø250~500um TANW CP-1 (ALL) TABR (ALL) |

P | 10x Spools | 50x Spools | - | - | |||

| No.88B 3.5 Inch  |

89mm | 10mm | 71mm | 3mm | 25mm | 31mm |

No.88B Ø100~200um TANW |

P | 10x Spools | 50x Spools | - | - | ||||

| No.88K 3.5-inch  |

88mm | 11mm | 50mm | 3mm | 31mm | 37mm | No.88K Ø100~600um TANW |

K | 10x Spools | 50x Spools | - | - | ||||

| No.120 4.75 Inch  |

120mm | 10mm | 54mm | 4mm | 30mm | 38mm |

No.120 Ø100~600um TANW CP-1 (ALL) TABR(ALL) |

R | 5x Spools | 20x Spools | - | - | ||||

| No.120K 4.75 Inch  |

120mm | 11mm | 64mm | 4mm | 30mm | 38mm |

No.120K Ø100~600um TANW |

T | 5x Spools | 20x Spools | - | - | ||||

| ||||||||||||||||

| Note 1: Cu and PCC Pd coated Cu requires grounded Spool. | ||||||||||||||||

| Note 2: Round Wire is wound forward/cross pattern (Cross wound-cross hatch wind) | ||||||||||||||||

| Note 3: Ribbon Wire is wound forward/parallel | ||||||||||||||||

| Note 4: Start wire on spool with Green tape. • End wire on spool with Red tape. | ||||||||||||||||

| Note 5: 2x white inner boxes fit into small outer box. 6x white inner boxes fit into medium outer box. 9x white inner boxes fit into large outer box. | ||||||||||||||||

| ± Tolerance Table | |||||||||

| Alloy | Ø Diameter | Tolerance | Spool | ||||||

| Au Gold Type GBC , GBE , GFC, GFD GHA-2 , GLD, GLF , GMB GMG , GMH-2 , GPG-2 , GPH GSA , GSB , M3 , Y , C |

Ø 15µm ~ 38µm (Ø 0.6 ~ 1.5 mil) |

±1 μm | AL2(W) Code A AL-4 Code B |

||||||

| Ø 40µm ~ 50µm (Ø 1.6 ~ 2.0 mil) |

±2 μm | ||||||||

| Ø 60µm ~ 100µm (Ø 2.4 ~ 4.0 mil) |

±3 μm | ||||||||

| Ø 125µm ~ 150µm (Ø 5.0 ~ 6.0 mil) |

±5 μm | ||||||||

| Ag Silver Type SEA, SEB, SEC |

Ø 15µm ~ 38µm (Ø 0.6 ~ 1.5 mil) |

±1 μm | |||||||

| Ø 40µm ~ 50µm (Ø 1.6 ~ 2.0 mil) |

±2 μm | ||||||||

| Al-1%Si Type TABN |

Ø 15µm ~ 38µm (Ø 0.6 ~ 1.5 mil) |

±1 μm | |||||||

| Ø 40µm ~ 38µm (Ø 1.6 ~ 2.0 mil) |

±2 μm | ||||||||

| Cu Copper Bare & Plated Type CLR1-AT , CHR-6BT , TCB1 , CA-1 CFB-1 , TPCW |

Ø 15µm ~ 38µm (Ø 0.6 ~ 1.5 mil) |

±1 μm | AL-4(WNi) Grounded Code N |

||||||

| Ø 40µm ~ 50µm (Ø 1.6 ~ 2.0 mil) |

±2 μm | ||||||||

| Ø 60µm ~ 70µm (Ø 2.4 ~ 2.8 mil) |

±3 μm | ||||||||

| Power Aluminum Type TANW |

Ø 100µm ~ 175µm (Ø 4.0 ~ 7.0 mil) |

±7 μm | 100~175μm • No. 88B 200~600μm • No.88 Polycarbonate Code P |

||||||

| Ø 200µm ~ 450µm (Ø 8.0 ~ 18 mil) |

±7 μm | ||||||||

| Ø 500µm ~ 600µm (Ø 20 ~ 24 mil) |

±10 μm | ||||||||

| Flat Ribbon Al Type TABR |

Width 0.8mm

(32 mil) Thick 0.1mm (4 mil) |

W: ±0.050mm T: ±0.015mm |

No. 88 • No.88B Polycarbonate Code P |

||||||

| Width 1.0mm

(32 mil) Thick 0.1mm (4 mil) |

W: ±0.050mm T: ±0.020mm |

||||||||

| Width 1.5mm

(60 mil) Thick 0.2mm (8 mil) |

W: ±0.075mm T: ±0.015mm |

No. 120 Polycarbonate Code R |

|||||||

| Width 2.0mm

(80 mil) Thick 0.2mm (8 mil) |

W: ±0.10mm T: ±0.020mm |

||||||||

| |||||||||

| Recommended Storage Conditions | |||||||||

| Alloy | Tanaka Type |

Warranty Period |

Time to Use Opened Package |

Storage Conditions | Notes | ||||

| Au Gold |

GBC , GBE , GFC, GFD GHA-2 , GLD, GLF , GMB GMG , GMBH , GPG , GPH GSA , GSB M3, C, Y FA AuR |

24-Months | 24-Months | Temp: 10~30°C Humidity: 70% Max |

Keep in Spool Case. Store in clean. environment |

||||

| |||||||||

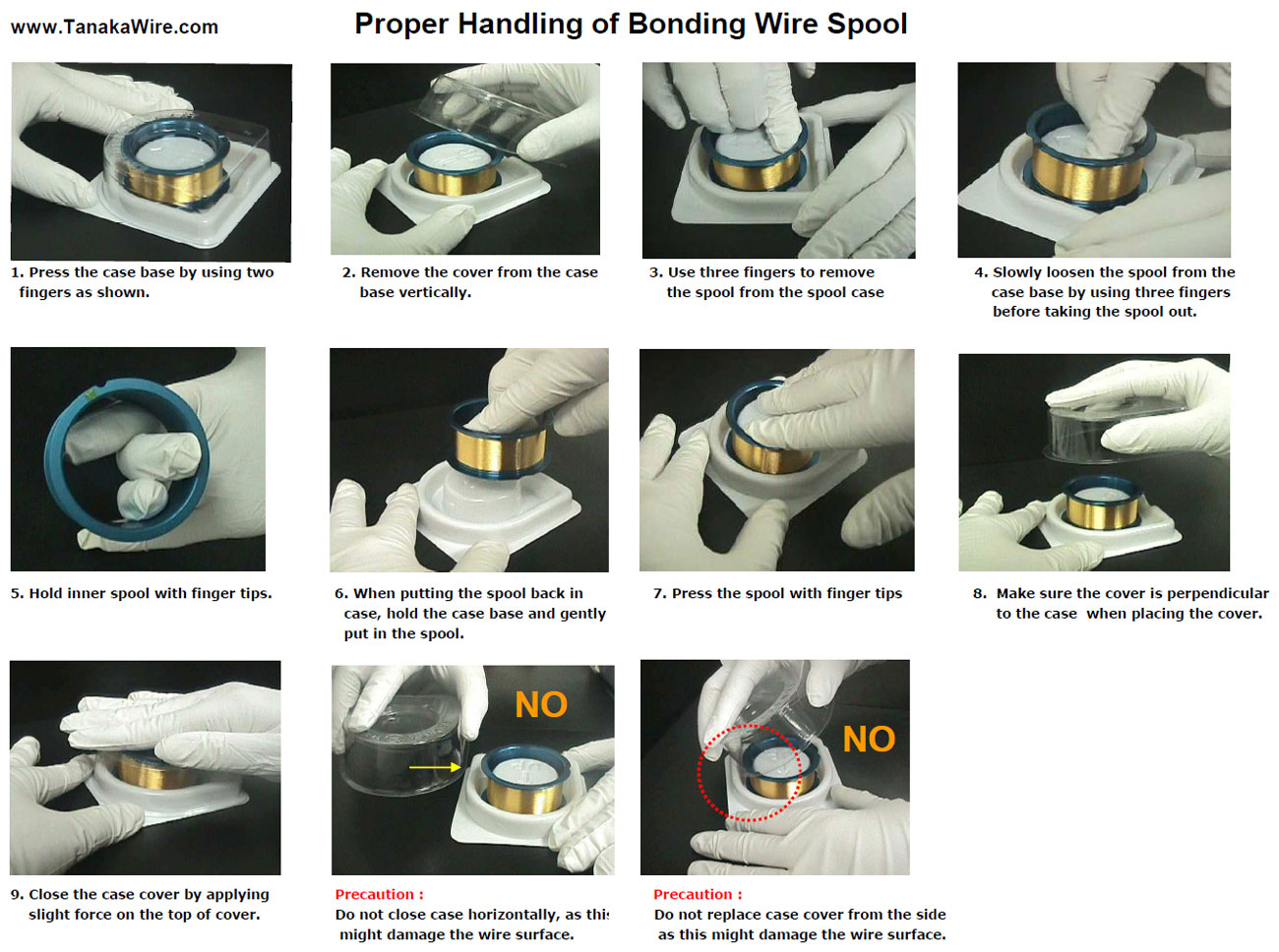

Handling Bonding Wire Spool

PDF

Green=Start • Red=End.  |

|||||||||

|

|||||||||

| |||||||||

| Difference between Gold Bump Wire and Gold Bonding Wire. | |||||||||

| Note | Feature | Bump Wire | Bonding Wire | ||||||

| 1 | Number of Bonds | One Bond Only To Die Pad or Substrate |

Two Bonds From Die Pad to Package. |

||||||

| 2 | Purpose/Application | Single Au (gold) wire is squashed. Wire is then reflowed (melted) to form a bump for a flip chip. |

Bonding from the die to the leadfame (or substrate) with a loop (wedge or stitch). | ||||||

| 3 | Repeatable Wire Break | Bumping wire is intended to break close to neck area of first bond. |

Bonding wire has a longer HAZ (heat affected zone) to permit the wire to be kinked or looped and pan out for next bond (wedge or stitch) |

||||||

| 4 | Grain Structure | Dopants added for grain structure during annealing process to allow repeatable wire break after the stud bump formation to make wire softer for wire cut/break mode. | Grain structure in bonding wire enables formation of loop or kink. |

||||||

| |||||||||

| EL - Elongation Summary Gold Wire Sorted by Type PDF |

|||||||||||||

| Type | Purity | Ø15μm 0.6 mil |

Ø18μm 0.7 mil |

Ø20μm 0.8 mil |

Ø23μm 0.9 mil |

Ø25μm 1.0 mil |

Ø28μm 1.1 mil |

Ø30μm 1.2 mil |

Ø32μm 1.25 mil |

Ø35μm 1.4 mil |

Ø38μm 1.5 mil |

Ø50μm 2.0 mil |

|

| C | 4N | - | - | 2.0~6.0% | 2.0~6.0% | 2.0~6.0% | 2.0~7.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 3.0~10% | - | |

| FA | 4N | - | - | 2.0~6.0% | 2.0~6.0% | 2.0~7.0% | 2.0~7.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 3.0~12% | - | |

| GBC | 2N | 1.5~4.0% | 1.5~4.0% | 1.5~4.0% | 1.5~4.0% | 1.5~5.0% | 1.5~5.0% | 1.5~5.0% | 1.5~5.0% | 1.5~6.0% | 1.5~6.0% | - | |

| GBE | 4N | 1.0~4.0% | 1.0~4.0% | 1.0~4.0% | 1.0~4.0% | 1.0~5.0% | 1.0~5.0% | 1.0~5.0% | 1.0~5.0% | 1.0~6.0% | 1.0~6.0% | - | |

| GFC | 4N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GFD | 4N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GHA-2 | 4N | - | - | 2.0~6.0% | 2.0~6.0% | 2.0~7.0% | 2.0~7.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 3.0~9.0% | - | |

| GLD-H | 4N | 3.5% Max | 3.5% Max | 3.5% Max | 3.5% Max | 3.5% Max | 3.5% Max | 3.5% Max | 3.5% Max | 4.5% Max | 4.5% Max | 4.5% Max | |

| GLD | 4N | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 3.0~10% | 3.0~10% | |

| GLF | 4N | 2.0~6.0% | 2.0~6.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~9.0% | - | - | - | - | |

| GMB-2 | 4N | - | - | 2.0~6.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 3.0~10% | - | |

| GMG | 4N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GMH | 4N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GMH-2 | 4N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GPG | 2N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GPG-2 | 2N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GPG-3 | 2N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | 2.0~7.0% | - | - | - | - | |

| GPH | 2N | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 2.0~8.0% | 2.0~8.0% | 2.0~8.0% | 2.0~8.0% | - | - | - | - | |

| GSA | 4N | 1.0~6.0% | 1.0~6.0% | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 1.5~8.5% | 1.5~8.5% | 1.5~8.5% | 1.5~8.5% | 1.5~8.5% | |

| GSB | 4N | 1.0~6.0% | 1.0~6.0% | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 1.0~7.0% | 1.5~8.5% | - | - | - | - | |

| M3 | 4N | - | - | 2.0~6.0% | 2.0~7.0% | 2.0~7.0% | 2.0~8.0% | 2.0~9.0% | 3.0~9.0% | 3.0~9.0% | 4.0~12% | 4.0~12% | |

| Y | 4N | - | - | 2.0~5.0% | 2.0~6.0% | 2.0~6.0% | 2.0~6.0% | 2.0~7.0% | 3.0~7.0% | 3.0~8.0% | 4.0~8.0% | - | |

| |||||||||||||

| Note 1: Actual elongation tends to be the middle of each range. Example: The EL of Ø25μm GSA is shown as 1.0~7.0% in above table. However average Ø25μm GSA EL tests around 4% | |||||||||||||

| BL - Breaking Load (g) Summary Gold Wire Sorted by Type PDF |

|||||||||||||

| Type | Purity | Ø15μm 0.6 mil |

Ø18μm 0.7 mil |

Ø20μm 0.8 mil |

Ø23μm 0.9 mil |

Ø25μm 1.0 mil |

Ø28μm 1.1 mil |

Ø30μm 1.2 mil |

Ø32μm 1.25 mil |

Ø35μm 1.4 mil |

Ø38μm 1.5 mil |

Ø50μm 2.0 mil |

|

| C | 4N | - | - | 4.5~8.0g | 5.5~9.5g | 7.5~11.5g | 11.0~15.0g | 11.0~15.5g | 13.0~18.0g | 15.0~25.0g | 18.0~28.0g | - | |

| FA | 4N | - | - | 5.0~8.7g | 6.5~11.5g | 7.7~13.5g | 9.7~17.0g | 11.1~19.5g | 12.7~22.2g | 15.2~26.5g | 17.9~31.3g | - | |

| GBC | 2N | ≥3.0g | ≥5.0g | ≥9.0g | ≥10.0g | ≥11.0g | ≥13.0g | ≥15.0g | ≥18.0g | ≥27.0g | ≥30.0g | - | |

| GBE | 4N | ≥3.0g | ≥6.0g | ≥8.0g | ≥12.0g | ≥14.0g | ≥17.0g | ≥20.0g | ≥23.0g | ≥27.0g | ≥32.0g | - | |

| GFC | 4N | 2.8~5.6g | 4.0~8.0g | 5.0~9.9g | 6.5~13.1g | 7.7~15.5g | 9.7~19.4g | 11.1~22.3g | - | - | - | - | |

| GFD | 4N | 3.3~6.1g | 4.8~8.8g | 5.9~10.8g | 7.8~14.3g | 9.2~16.9g | 11.5~21.2g | 13.2~24.4g | - | - | - | - | |

| GHA-2 | 4N | - | - | 4.0~8.0g | 7.0~11.0g | 9.0~13.0g | 11.0~16.0g | 13.0~18.0g | 15.0~21.0g | 19.0~25.0g | 21.0~30.0g | - | |

| GLD-H | 4N | ≥2.5g | ≥4.0g | ≥6.0g | ≥10.0g | ≥16.0g | ≥18.0g | ≥20.0g | ≥23.0g | ≥27.0g | ≥35.0g | ≥45.0g | |

| GLD | 4N | 1.7~3.7g | 4.9~7.4g | 6.0~9.0g | 8.0~12.0g | 10.0~14.0g | 12.0~17.0g | 14.0~20.0g | 15.0~23.0g | 19.0~27.0g | 22.0~35.0g | 32.0~45.0g | |

| GLF | 4N | 3.1~5.9g | 4.5~8.5g | 5.6~10.5g | 7.4~13.9g | 8.7~16.4g | 10.9~20.6g | 12.5~23.7g | - | - | - | - | |

| GMB-2 | 4N | - | - | 5.0~9.0g | 7.5~11.5g | 9.0~14.0g | 11.0~16.0g | 13.0~19.0g | 15.0~22.0g | 20.0~26.0g | 23.0~33.0g | - | |

| GMG | 4N | 3.6~6.4g | 5.1~9.1g | 6.3~11.3g | 8.4~14.9g | 9.9~17.6g | 12.4~22.1g | 14.3~25.4g | - | - | - | - | |

| GMH | 4N | 3.7~5.7g | 5.4~8.1g | 6.7~10.1g | 8.8~13.3g | 10.4~15.7g | 13.0~19.7g | 15.0~22.6g | - | - | - | - | |

| GMH-2 | 4N | 3.7~6.5g | 5.4~9.4g | 6.7~11.6g | 8.8~15.3g | 10.4~18.1g | 13.0~22.7g | 15.0~26.1g | - | - | - | - | |

| GPG | 2N | 3.7~5.7g | 5.4~8.1g | 6.7~10.1g | 8.8~13.3g | 10.4~15.7g | 13.0~19.7g | 15.0~22.6g | - | - | - | - | |

| GPG-2 | 2N | 3.5~6.3g | 5.0~9.0g | 6.2~11.1g | 8.9~16.0g | 9.7~17.4g | 12.1~21.8g | 13.9~25.1g | 15.0~23.0g | 19.0~27.0g | - | - | |

| GPG-3 | 2N | 3.3~6.1g | 4.8~8.8g | 5.9~10.8g | 7.8~14.3g | 9.2~16.9g | 11.5~21.2g | 13.2~24.4g | - | - | - | - | |

| GPH | 2N | 3.3~6.1g | 4.8~8.8g | 5.9~10.8g | 7.8~14.3g | 9.2~16.9g | 11.5~21.2g | 13.2~24.4g | - | - | - | - | |

| GSA | 4N | 2.5~5.3g | 3.6~7.6g | 4.4~9.4g | 5.9~12.5g | 7.0~14.7g | 8.7~18.5g | 10.0~21.1g | 11.4~24.0g | - | 16.0~33.8g | 27.6~58.3g | |

| GSB | 4N | 2.9~5.7g | 4.2~8.2g | 5.2~10.1g | 6.9~13.5g | 8.1~15.8g | 10.2~19.9g | 11.6~22.7g | - | - | - | - | |

| M3 | 4N | - | - | 6.0~9.0g | 7.0~11.5g | 9.0~13.5g | 12.0~17.0g | 13.0~18.0g | 15.0~20.0g | 18.0~26.0g | 20.0~30.0g | 30.0~50.0g | |

| Y | 4N | - | - | 3.5~6.6g | 6.4~8.1g | 6.5~11.4g | 8.5~14.7g | 10.0~17.1g | 11.4~19.5g | 14.0~23.6g | 17.6~28.9g | - | |

| |||||||||||||

| Note 1: Actual elongation tends to be the middle of each range. Example: The EL of Ø25μm GSA is shown as 1.0~7.0% in above table. However average Ø25μm GSA EL tests around 4% | |||||||||||||

| RLC Parametric Data | |||||||||

| Material Alloy |

Ø Mil | Ø um | R milli-ohm/mm 0 Hz (DC) |

R milli-ohm/mm 100 MHz |

Ls nH/mm 100~400 MHz |

Cs pF/mm 100~400 MHz |

|||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

0.6mil | 15um | 163.62 191.44 115.70 |

237.01 277.31 177.42 |

1.184 | 0.073 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

0.7mil | 18um | 119.98 140.38 84.83 |

182.77 213.85 137.64 |

1.140 | 0.077 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

0.8mil | 20um | 91.74 107.24 64.76 |

148.55 173.65 111.01 |

1.114 | 0.081 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

0.9mil | 23um | 72.24 84.45 51.07 |

122.39 143.07 92.37 |

1.074 | 0.085 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

1.0mil | 25um | 58.40 68.27 41.25 |

103.47 120.95 79.02 |

1.043 | 0.092 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

1.1mil | 28um | 49.08 56.21 33.99 |

88.68 103.66 68.40 |

1.012 | 0.098 | |||

| Gold (4N Au) Gold (2N Au) PCC (4N Cu) |

1.2mil | 30um | 40.54 47.40 28.66 |

78.62 91.90 60.52 |

1.010 | 0.104 | |||

| |||||||||

| RLC Electrical Parametric Data PDF | |||||||||

| Electrical Resistance Ω Ohms per 10mm Length | ||||||||||||

| Symbol | Material | Ø15μm 0.6 mil |

Ø18μm 0.7 mil |

Ø20μm 0.8 mil |

Ø25μm 1.0 mil |

Ø30μm 1.2 mil |

Ø32μm 1.25 mil |

Ø33μm 1.3 mil |

Ø35μm 1.4 mil |

Ø38μm 1.5 mil |

Ø50μm 2.0 mil |

Resistivity μΩ•cm |

| Au | 4N Gold | 1.30 | 0.49 | 0.73 | 0.47 | 0.33 | 0.29 | 0.27 | 0.24 | 0.20 | 0.12 | 2.3 |

| Au | 2N Gold | 1.75 | 1.22 | 0.99 | 0.63 | 0.44 | 0.39 | 0.36 | 0.32 | 0.27 | 0.16 | 3.1 |

| Cu | CLR1-A | 1.08 | 0.75 | 0.61 | 0.39 | 0.27 | 0.24 | 0.22 | 0.20 | 0.17 | 0.10 | 1.9 |

| Cu | CFB-1 | 1.08 | 0.75 | 0.61 | 0.39 | 0.27 | 0.24 | 0.22 | 0.20 | 0.17 | 0.10 | 1.9 |

| Cu | CA-1 | 1.24 | 0.86 | 0.70 | 0.45 | 0.31 | 0.27 | 0.26 | 0.23 | 0.19 | 0.11 | 2.2 |

| Ag | SEA | 2.66 | 1.85 | 1.50 | 0.96 | 0.67 | 0.58 | 0.55 | 0.49 | 0.41 | 0.24 | 4.7 |

| Ag | SEB | 1.87 | 1.30 | 1.05 | 0.67 | 0.47 | 0.41 | 0.39 | 0.34 | 0.29 | 0.17 | 3.3 |

| Ag | SEC | 1.47 | 1.02 | 0.83 | 0.53 | 0.37 | 0.32 | 0.30 | 0.27 | 0.23 | 0.13 | 2.6 |

| Al | Al-1%Si TANW |

1.75 | 1.22 | 0.99 | 0.56 | 0.44 | 0.39 | 0.36 | 0.32 | 0.27 | 0.16 | 3.1 |

| Power Al Wire - Electrical Resistance Ω Ohms per 10mm Length | ||||||||||||||

| Symbol | Material | Ø100μm 4mil |

Ø125μm 5mil |

Ø150μm 6mil |

Ø175μm 7mil |

Ø200μm 8mil |

Ø250μm 10mil |

Ø300μm 12mil |

Ø350μm 14mil |

Ø380μm 15mil |

Ø400μm 16mil |

Ø450μm 18mil |

Ø500μm 20mil |

Resistivity μΩ•cm |

| Al | TANW | 0.0344 | 0.0220 | 0.0153 | 0.0112 | 0.0086 | 0.0055 | 0.0038 | 0.0028 | 0.0024 | 0.0021 | 0.0017 | 0.0014 | 2.7 |

| ||||||||||||||

| Physical Properties (General) | |||||||

| Item | Unit | Gold | Copper | Aluminum | Silver | Palladium | Platinum |

| Atomic Symbol | Au | Cu | Al | Ag | Pd | Pt | |

| Atomic Number | 79 | 29 | 13 | 47 | 46 | 78 | |

| Atomic Weight | 196.96655 | 63.546 | 26.981538 | 107.8682 | 106.42 | 195.078 | |

| Melting Point | K | 1336 | 1356 | 933 | 1234 | 1825 | 2042 |

| Density (20°) | g • cm-3 | 19.32 | 8.92 | 2.70 | 10.50 | 12.02 | 21.45 |

| Resistivity (20°) | μΩ • cm | 2.300 | 1.694 | 2.700 | 1.630 | 10.80 | 10.58 |

| Thermal Conductivity (0~100°) | Wm-1 • K-1 | 315.5 | 397 | 238 | 425 | 75.2 | 73.4 |

| Specific Heat (0~100°) | JKg-1 • K-1 | 130 | 386 | 917 | 234 | 247 | 134.4 |

| CTE (0~100°) | PPM/°C | 14.1 | 17.0 | 23.5 | 19.1 | 11.0 | 9.0 |

| Young's Modulus | G•Pa | 88.3 | 136 | 69 | 100.5 | 121 | 169.9 |

| Shear Modulus | G•Pa | 29.6 | - | 26.0 | 31.3 | - | - |

| |||||||

| Physical Properties By Wire Type | |||||||

| Item | Unit | Gold 4N-Au GFC Type |

Silver Alloy SEC Type |

Bare Copper 4N Cu CFB-1 Type |

Coated Copper 4N PCC CLR-1AT CHR Type |

Test Method | |

| Hardness Free Air Ball Hardness of Wire |

Hv | 30~50Hv 65~85Hv |

45~65Hv 65~85Hv |

55~75Hv 60~80Hv |

60~80Hv 70~90Hv |

Vickers Tester | |

| Density (20°C) |

g / cm3 | 19.32 | 10.54 | 8.92 | 8.97 | ASTM | |

| Thermal Conductivity (0~100°) |

W/m per K | 315.5 | 281.5 | 385 | 385 | Theoretical Value | |

| Linear CTE (0~100°) |

PPM/°K | 14.1 | 19.0 | 17.0 | 17.0 | Metals Data Book | |

| Elastic Modulus | G•Pa | 65~85 | 50~70 | 50~90 | 60~85 | Tensile Tester | |

| Resistivity (20°C) |

μΩ • cm | 2.3 | 2.6 | 1.9 | 19 | Kelvin Method 4-terminal |

|

| Melting Point | °C | 1063°C | 980°C | 1084°C | 1084°C | Theoretical Value | |

| |||||||

| Wire Part Number System | |||||||||

| GSA | - | 25 | A | 100 | |||||

| Type | Ø Diameter µm | Spool Type | Length Meters | Options | |||||

|

Gold 4N (Au99.99%) GSA = (300xxx) Stable Stitch GBE = (301xxx) Bumping Wire GMH-2 = (302xxx) High Strength M3 = (303xxx) Standard Wire GFD = (306xxx) Fine Pitch GLF = (307xxx) Low Loop GLD-H = (309xxx) Wedge to Wedge AuR = (316xxx/326xxx) Au Ribbon AuR3 = (353xxx) Au Ribbon Be Doping AuS = Au Ribbon Gold 2N (Au99%) Alloy GPG-2 = (304xxx) High Reliability GPG = (335xxx) High Reliability GBC = (305xxx) Bumping Wire GPH = (308xxx) High Reliability Gold (Other) FA = (330xxx) Soft Touch Y = (331xxx) Soft Touch GMG = (332xxx) High Strength GMH = (333xxx) High Strength GFC = (334xxx) Fine Pitch GPG = (335xxx) 2N Au Alloy GSB = (336xxx) Stable Stitch GMB-2 = (337xxx) Smart Card GHA-2 = (338xxx) High Loop GL-2 = (339xxx) High Strength C = (340xxx) Legacy GPG-3 = (341xxx) Hi Rel GLD = (349xxx) Wedge to Wedge Aluminum TANW = Al Round TABR = Al Ribbon TALF = 99% Al TABN = Al-1%Si TABW = Al-1%Si Silver Ag Alloy SEA = Silver SEB = Silver SEC = Silver Palladium Pd Coated Copper CLR-1AT = 4N Pd Cu - Original Chemistry CLR-2AT = 4N Pd Cu - Enhanced Chemistry CHR-2BT = 4N Pd Cu - Standard Chemistry CHR-5BT = 3N Pd Cu - Fine Pitch High Rel CHR-6BT = 2N Pd Cu - Automotive Hi Rel Bare Copper CA-1 = 2N Copper Alloy CFB-1 = 4N Standard Bare Cu CP-1 = 4N Cu High Power Obsolete Copper TPCW = 4N High Purity TCA1 = 4N Cu Fine Pitch TCB1 = 4N Cu Good Stitch |

Code Mil 12.5 0.5mil 15 0.6mil 18 0.7mil 20 0.8mil 23 0.9mil 25 1.0mil 28 1.1mil 30 1.2mil 32 1.25mil 33 1.3mil 35 1.4mil 38 1.5mil 50 2.0mil 60 2.4mil 70 2.7mil 75 3.0mil 80 3.2mil TANW Large Dia Wire µm Mil 100µm 4mil 125µm 5mil 150µm 6mil 175µm 7mil 200µm 8mil 250µm 10mil 300µm 12mil 350µm 14mil 380µm 15mil 400µm 16mil 450µm 18mil 500µm 20mil 600µm 24mil Al Ribbon Wire 800x100 = 30 x 4.0mil 1000x100 = 40 x 4.0mil 1500x200 = 60 x 8.0mil 2000x200 = 80 x 8.0mil More Ribbon Sizes Au Ribbon Wire 38x12.7 = 1.5 x 0.5mil 50x12.7 = 2.0 x 0.5mil 75x12.7 = 3.0 x 0.5mil 100x12.7 = 4.0 x 0.5mil 125x12.7 = 5.0 x 0.5mil 150x12.7 = 6.0 x 0.5mil - - - - - - 50x25 = 2.0 x 1.0mil 75x25 = 3.0 x 1.0mil 100x25 = 4.0 x 1.0mil 125x25 = 5.0 x 1.0mil 150x25 = 6.0 x 1.0mil 200x25 = 8.0 x 1.0mil 250x25 = 10 x 1.0mil - - - - - - 125x50 = 5.0 x 2.0mil More Ribbon Sizes |

Aluminum Spool A = 2"x1" AL-2W Spool B = 2"x2" AL-4 Spool H = 1/2" x 3/4" 1/2-Inch Spool AL-1/2 Spool Aluminum Spool Conductive Nickel Core Grounded C = 2"x1" AL-2 WNI Spool N = 2"x2" AL-4 WNi Spool Cu Wire Polycarbonate Spool P = 3.5"x1.25" No.88 TABR=Al Ribbon CP-1 Copper K = 3.5"x1.25" No.88K TANW=Power Aluminum R = 4.7"x1.50" No.120 TABR=Al Ribbon CP-1=Copper T = 4.7"x1.50" No.120K TANW=Power Aluminum |

Meters Feet 25 75ft 50 150ft 100 300ft 200 600ft 300 1000ft 400 1300ft 500 1500ft 1000 3000ft 2500 8000ft 5000 16000ft Meters controlling dimension Go to: 1/2" Spools |

Blank = Standard Green=Start Red=End. A = Rev A B = Rev B etc |

|||||

| |||||||||

|

Wire Order Number |

|||||||||

| 3 | 0 | 2 | 25 | 1 | |||||

| Alloy | Shape | Type | Ø Diameter | Length | |||||

|

Code • Description 3 = Gold (Au) 4 = Aluminum (Al) 5 = Silver (Ag) 7 = Copper (Cu) |

Code Description 0 = Round Wire 3 = Round Wire 4 = Round Wire 1 = Flat Ribbon 2" Spool 2 = Flat Ribbon 1/2" Spool 5 = Flat Ribbon 2" Spool |

Round Gold Wire (Au) 0 = GSA 1 = GBE 2 = GMH-2 3 = M3 4 = GPG-2 5 = GBC 6 = GFD 7 = GLF 8 = GPH 9 = GLD-H Round Gold Wire (Au) More 30 = FA 31 = Y 32 = GMG 33 = GMH 34 = GFC 35 = GPG 36 = GSB 37 = GMB-2 38 = GHA-2 39 = GL-2 40 = C 41 = GPG-3 49 = GLD Flat Gold Wire (Au) 6 = AuR 53 = AuR3 Be Doping Aluminum Wire (Al) 1 = TALF (Discontinued) 2 = TABR 3 = TABN 4 = TABW 5 = TANW Silver Wire (Ag) 1 = SEA 2 = SEB 3 = SEC Copper Wire (Cu) 0 = CLR-1AT (4N Pd Coated Cu) 1 = CA-1 (2N Bare Cu Alloy) 2 = CFB-1 (4N Bare Cu) 3 = CHA (Discontinued) 4 = CHR-2BT (4N Pd Coated Cu) 5 = CHR-5BT (3N Pd Coated Cu) 6 = CHR-6BT (2N Pd Coated Cu) 7 = CP-1 (4N Bare Power Cu) 8 = CLR-2AT (4N Pd Coated Cu) 9 = Future |

µm Mil 12 0.5mil 15 0.6mil 18 0.7mil 20 0.8mil 23 0.9mil 25 1.0mil 28 1.1mil 30 1.2mil 32 1.25mil 33 1.3mil 38 1.5mil 50 2.0mil 60 2.4mil 70 2.7mil 75 3.0mil 80 3.2mil TANW, CP-1 and Y Large Dia Wire Code µm Mil 00 100µm 4mil 01 125µm 5mil 02 150µm 6mil 03 175µm 7mil 04 200µm 8mil 05 250µm 10mil 06 300µm 12mil 07 350µm 14mil 08 380µm 15mil 09 400µm 16mil 10 450µm 18mil 11 500µm 20mil 12 600µm 24mil Al Ribbon Wire 48 = 0.8 x 0.1mm 49 = 1.0 x 0.1mm 85 = 1.5 x 0.2mm 86 = 2.0 x 0.2mm Au Ribbon Wire 51 = 25 x 12.7um 38 = 38 x 12.7um 50 = 50 x 12.7um 52 = 75 x 12.7um 53 = 100 x 12.7um 54 = 125 x 12.7um 55 = 150 x 12.7um - - - - 10 = 50 x 25um 11 = 75 x 25um 12 = 100 x 25um 13 = 125 x 25um 14 = 150 x 25um 15 = 200 x 25um 16 = 250 x 25um - - - - 22 = 125 x 50um More Ribbon Sizes |

Code Meters Feet 9 = 25m (75ft) 0 = 50m (150ft) 1 = 100m (300ft) 2 = 200m (600ft) 3 = 300m (1000ft) 4 = 400m (1300ft) 5 = 500m (1500ft) 6 = 1000m (3000ft) 7 = 2500m (8000ft) 8 = 5000m (16000ft) Meters controlling dimension Go to: 1/2" Spools |

|||||

| |||||||||

|

| |

|

||||||||||||||||||||||||||||